In the current practice, the process of cleaning validation became essential for the life science sector, especially for the pharmaceutical sector but also for the medical device sector. Cleaning validation can be defined as a set of procedures to establish evidence that cleaning processes for manufacturing equipment prevents product contamination. It is important to remember that cross-contamination of chemical residues or microbes might affect the safety of the patient in relation to the use of API (Active Pharmaceutical Ingredients). Moreover, this could result in the so-called “Drug Adulteration”, which is typically sanctioned by competent authorities, such as FDA.

Guidelines for the Cleaning Validation Process

There are different guidelines issued by different authorities which provide guidance on the requirements for the cleaning process and suggestions on the strategy for Cleaning Validation activities.

- FDA Cleaning Validation Guideline from CFR 211.67

- FDA CFR 211 – Current Good Manufacturing Practice for Finished Pharmaceuticals

- EMA Cleaning Guidance

- EMA Cleaning Validation Guideline on setting HBELs

- QnA on the implementation of the above guideline EMA

- ISPE Cleaning Validation Guide

- WHO Cleaning Guidance

FDA Requirements related to Cleaning Process

First of all, it is essential to have specific SOP related to the cleaning process of the various types of equipment used in the API production. The SOP should reflect the current policy of the organization in relation to the cleaning process. Thus, for example, the organization might take in consideration to use a specific cleaning process for cleaning activities within different batches of the same product and use a different cleaning processes between different batches of different API.

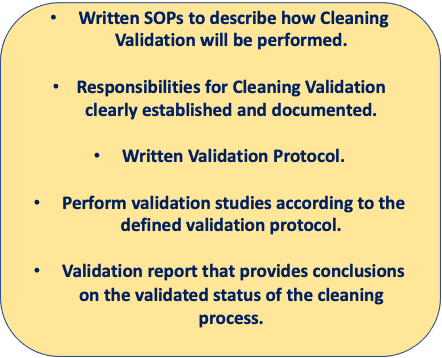

The other important requirement for the cleaning process is the validation. In this context it is essential to address the following aspects which can be summarized in the scheme below:

Cleaning Validation SOP

Given the importance of the cleaning validation process, it is essential to have written SOPs that defines how cleaning validation shall be performed? The extent of details to be mentioned within the Cleaning Validation SOPs depends from different factors mainly linked to the organization of the cleaning process. However it is essential that the Cleaning validation SOP reflects the standard practice within the organization.

In the coming section, we will provide an overview of the main contents that should typically stay within a Cleaning Validation SOP.

- Objective : typically, the objective of the cleaning validation process is to ensure purity of the API and avoid any type of cross-contamination that could potentially affect patient safety.

- Scope the scope of the SOP is to provide detailed guidance on the modalities to be used for the validation of the cleaning process.

- Responsibilities: This section is highly dependent from the singular organization, however it is essential to identify the personnel responsible to perform the validation studies and the ones that will bring the responsibility for the final approval of the validation report.

- Cleaning Validation Protocol : This is a classic validation protocol, thus should reflect the contents of a standard protocol for validation activities. However, considering it is in the framework of a cleaning process, the protocol should address all the variables that need to be taken in consideration for this purpose. This includes, for example:

- Cleaning and sanitizing agents used

- Quality of water /solvents used

- Requirements related to the disassembly and re-assembly of the equipment, that might be necessary to perform an appropriate cleaning validation study.

- Temperature and pressure parameters

- Flow rates for washing rinses

- Duration/ timing for each steps of the cleaning process

- Volume used for each specific rinses.

- Agitation, recirculation and reflux

- Verification of cleaning (visual, analytic methods)

- Method to protect clean equipment from contamination

- Frequency of cleaning

- Moreover, the protocol should identify the most sensitive product for contamination on the basis of maximum daily dose & minimum batch.

- Analytic Method Validation The analytical methods used to validate the cleaning process should also be validated before the cleaning validation is performed. The methods chosen should detect residuals or contaminants specific for the substance(s) being assayed at an appropriate level of cleanliness (sensitivity).

The validation of the analytical method should include different aspects such as :

- precision, linearity and selectivity

- limit of detection (LOD);

- limit of quantization (LOQ);

- recovery, by spiking with the analyze

- Reproducibility.

- Acceptance limits The acceptance criteria established for contaminant levels in the sample should be practical, achievable and verifiable. A rationale should be provided for the residue limits established. Of course, each situation should be assessed individually ; however, the manner in which limits are established should be carefully considered. In establishing residual limits, it may not be adequate to focus only on the principal reactant, because other chemical variations may be more difficult to remove. It is important to mention that regulatory authorities do not set limits for specific products. Thus risk assessment consideration shall be included when decisions on the limits are performed.

The Sampling Methods

The sampling methods is of fundamental importance for the process of cleaning validation. There are different sampling methods that can be taken in consideration such as:

- Swab

- Rinse

- Visual Inspection

- Placebo

The swab is one of the principal sampling method. It has the advantage to be a direct sampling method and to be reproducible; furthermore it is easy to document the exact location from where the sample is taken using swab as sampling methodology. At the same time, the disadvantages are the impossibility to apply the method to area which are difficult to reach and the assumption of the uniformity of the contamination on sampling area.

Another standard method is the rinse. This is an indirect sampling method which is useful for highly soluble residues; it can surely reach surfaces which are typically difficult to access and can be used to sample very large surface.

Visual inspection of the cleaning surface shall always be included, when possible, as method to verify the results of the cleaning process. It can be performed during the disassembly of the equipment; however, if the equipment remains dirty after the cleaning process it is difficul to apply this method.

Analytical Methods Used to Verify the Cleaning Process

As mentioned before, the analytical method used to validate the cleaning process shall also be validated. There are different analytical methods that could potentially be used for the validation of cleaning process.

There are “specific” methods (thus methods that could detect the amount of substances) which could include chromatographic methods (High Performance Liquid Chromatography, Gas-Chromatography) or Elisa (enzyme-linked immunosorbent assay).

There are as well indirect methods, that could be used although no specific indications on the exact amount of the specific substances are provided. These methods include pH, conductivity and UV-absorption measurements.

-

Process Validation Procedure€64,00

Process Validation Procedure€64,00

Conclusions

In conclusions, we have provided an overview of the main requirements associated to the cleaning validation process mainly for pharmaceutical industry. Obviously the topics is rather large and complex, thus for the moment we have provided just a high level overview of the requirements associated to the cleaning process and the approaches to be used for cleaning validation. It is essential to understand the importance of the cleaning process to exclude cross-contamination of API production and that risk management should always be included when taking any type of decision or approach during the validation activities.

Subscribe to 4EasyReg Newsletter

4EasyReg is an online platform dedicated to Quality & Regulatory matters within the medical device industry. Have a look to all the services that we provide: we are very transparent in the pricing associated to these consulting services.

Within our WebShop, a wide range of procedures, templates, checklists are available, all of them focused on regulatory topics for medical device compliance to applicable regulations. Within the webshop, a dedicated section related to cybersecurity and compliance to ISO 27001 for medical device organizations is also present.

As one of the leading online platforms in the medical device sector, 4EasyReg offers extensive support for regulatory compliance. Our services cover a wide range of topics, from EU MDR & IVDR to ISO 13485, encompassing risk management, biocompatibility, usability, software verification and validation, and assistance in preparing technical documentation for MDR compliance.

Do not hesitate to subscribe to our Newsletter!