Article 17 of the EU MDR 2017/745 provides comprehensive guidelines regarding the requirements for the reprocessing of single-use devices. The significance of these requirements has been widely acknowledged, and numerous articles have already been published addressing the EU MDR and its implications for single-use devices. Notably, the ISO 17664 standard focuses on the processing instructions that manufacturers must supply for such devices.

In this article, our primary focus will be on the specific requirements outlined in the EU MDR 2017/745 concerning the reprocessing of single-use devices. Before delving into these requirements, it is crucial to revisit the definition of reprocessing as defined in Article 2 of the EU MDR. Reprocessing refers to the series of procedures performed on a previously used device to ensure its safe reuse. These procedures encompass cleaning, disinfection, sterilization, as well as related steps that aim to restore the technical and functional safety of the device.

Now, let us explore the specific requirements set forth in Article 17 of the EU MDR. These requirements encompass various aspects related to the reprocessing of single-use devices, including:

- Cleaning: The process of thoroughly removing contaminants and residues from the device’s surface to ensure its cleanliness and safe reuse.

- Disinfection: The application of appropriate methods and agents to eliminate or reduce the microbial load on the device, thereby minimizing the risk of infection transmission upon reuse.

- Sterilization: The use of validated sterilization methods to completely eliminate microorganisms and achieve a state of sterility, ensuring the device’s safety for subsequent use.

- Testing: Conducting rigorous testing procedures to assess the device’s technical and functional integrity after reprocessing. This ensures that the device meets the necessary safety and performance standards.

- Technical and functional safety restoration: Implementing measures to restore the device’s technical and functional characteristics to their original state, ensuring optimal performance and minimizing risks associated with reuse.

Overview of Article 17 of EU MDR 2017/745

First and foremost, it is crucial to reiterate that the reprocessing of single-use devices is permissible only if it is authorized by the national laws of the respective country. However, for devices bearing the CE marking, full compliance with the requirements outlined in Article 17 of the EU MDR is mandatory.

The role of the reprocessing device manufacturer holds significant importance. Any individual or legal entity engaged in the reprocessing of a single-use device is considered the manufacturer of the reprocessed device. Consequently, they are obligated to fulfill all the responsibilities specified within the EU MDR 2017/745.

Under certain circumstances, where there is no discernible difference in safety between the original device and the reprocessed device, and the reprocessing activities align with the relevant Common Specifications, some obligations outlined in the EU MDR may not be applicable.

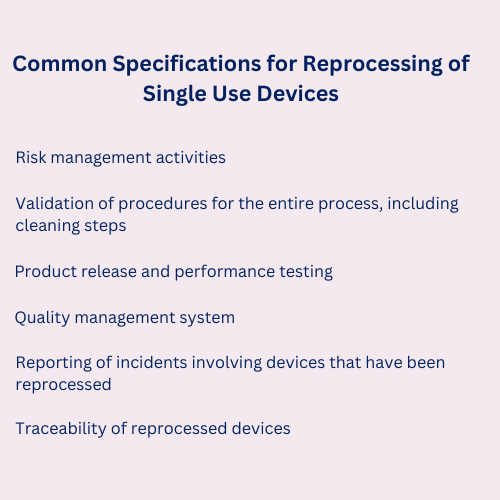

In previous sections, we have extensively discussed the Common Specifications pertaining to the reprocessing of single-use devices. Broadly speaking, these Common Specifications define the obligations related to the following aspects:

- Reprocessing Procedures: The detailed guidelines and protocols governing the various steps involved in reprocessing, including cleaning, disinfection, sterilization, and other related procedures.

- Quality Management System: The establishment and implementation of a robust quality management system to ensure the consistent and reliable reprocessing of single-use devices.

- Risk Management: The identification, assessment, and mitigation of risks associated with the reprocessing process, aiming to safeguard patient safety and minimize any potential hazards.

- Performance Testing: The requirements for conducting comprehensive performance testing to verify the functionality, integrity, and safety of reprocessed devices, thus ensuring their suitability for subsequent use.

- Labeling and Documentation: The specifications regarding labeling requirements, such as clear indications that the device has been reprocessed, along with the accurate and comprehensive documentation of the reprocessing activities and their outcomes. Among the documentation aspect, reporting of incidents involving reprocessed device is also a very important activity.

The requirement set by this Common Specifications shall be applicable in case the reprocessing activity is performed by an external Reprocessor, in case this si requested by a health institution.

The name and address of the legal or natural person referred that performs the reprocessing activity and shall be indicated on the label and, where applicable, in the instructions for use of the reprocessed device.

Labelling Information for Reprocessed Single Use Devices

Within Annex I of the EU MDR 2017/745, specific requirements concerning the labeling of reprocessed single-use devices have been established. When a device is a single-use device that has undergone reprocessing, certain information must be included in the device’s Information for Use. This information comprises an indication of the device being reprocessed, the number of reprocessing cycles already conducted, and any limitations regarding the number of reprocessing cycles.

In addition, the label of reprocessed single-use devices should prominently display the term “reprocessed.” Furthermore, the label must indicate the status of the single-use device, whether it has been “disinfected” or “sterilized,” along with details of the specific disinfection or sterilization method employed and the device’s shelf life. It is essential to provide clear and accurate information to users and healthcare professionals to ensure proper handling and usage.

The label and instructions for use of the single-use device should also contain the name and address of the health institution, as well as the external reprocessor’s details (if applicable). This information aids in identifying the entities responsible for reprocessing the device and provides necessary contact information.

By adhering to these labeling requirements, manufacturers of reprocessed single-use devices contribute to enhancing transparency and traceability in the healthcare sector. Users and healthcare professionals can readily identify reprocessed devices, understand their specific reprocessing history, and make informed decisions regarding their usage. Additionally, the inclusion of clear labeling information fosters accountability and facilitates effective communication among relevant stakeholders, ultimately promoting patient safety and the delivery of high-quality healthcare services.

Traceability Requirements for Single Use Reprocessed Devices

The maintenance of traceability is of utmost importance throughout the entire reprocessing cycle and the lifespan of the reprocessed single-use device. An effective traceability system must be in place to ensure the following key aspects:

Firstly, it is crucial to record the number of reprocessing cycles that the single-use device has undergone. This information allows for proper monitoring of the device’s history and helps determine if it has reached its maximum allowable number of reprocessing cycles. By accurately documenting the number of cycles, healthcare providers can make informed decisions regarding the continued usability and safety of the reprocessed device.

Secondly, the health institution plays a vital role in the verification process. It is responsible for ensuring that the single-use device, which has been reprocessed by an external reprocessor and subsequently returned to the health institution, is indeed the same device that was initially used within the institution and sent to the external reprocessor for reprocessing. This verification process is essential for maintaining the integrity and traceability of the reprocessed device, eliminating any potential mix-ups or confusion.

By establishing a robust traceability system that encompasses both the recording of reprocessing cycles and the verification process, healthcare facilities can confidently rely on reprocessed single-use devices. The traceability system acts as a safeguard, ensuring that the device’s history is accurately documented and that there is no compromise in patient safety or the quality of healthcare delivery. Effective traceability promotes transparency, accountability, and confidence in the reprocessing of single-use devices, thereby contributing to the overall safety and efficacy of healthcare practices.

Subscribe to 4EasyReg Newsletter

4EasyReg is an online platform dedicated to Quality & Regulatory matters within the medical device industry. Have a look to all the services that we provide: we are very transparent in the pricing associated to these consulting services.

Within our WebShop, a wide range of procedures, templates, checklists are available, all of them focused on regulatory topics for medical device compliance to applicable regulations. Within the webshop, a dedicated section related to cybersecurity and compliance to ISO 27001 for medical device organizations is also present.

As one of the leading online platforms in the medical device sector, 4EasyReg offers extensive support for regulatory compliance. Our services cover a wide range of topics, from EU MDR & IVDR to ISO 13485, encompassing risk management, biocompatibility, usability, software verification and validation, and assistance in preparing technical documentation for MDR compliance.

Do not hesitate to subscribe to our Newsletter!